Our Laser Centre

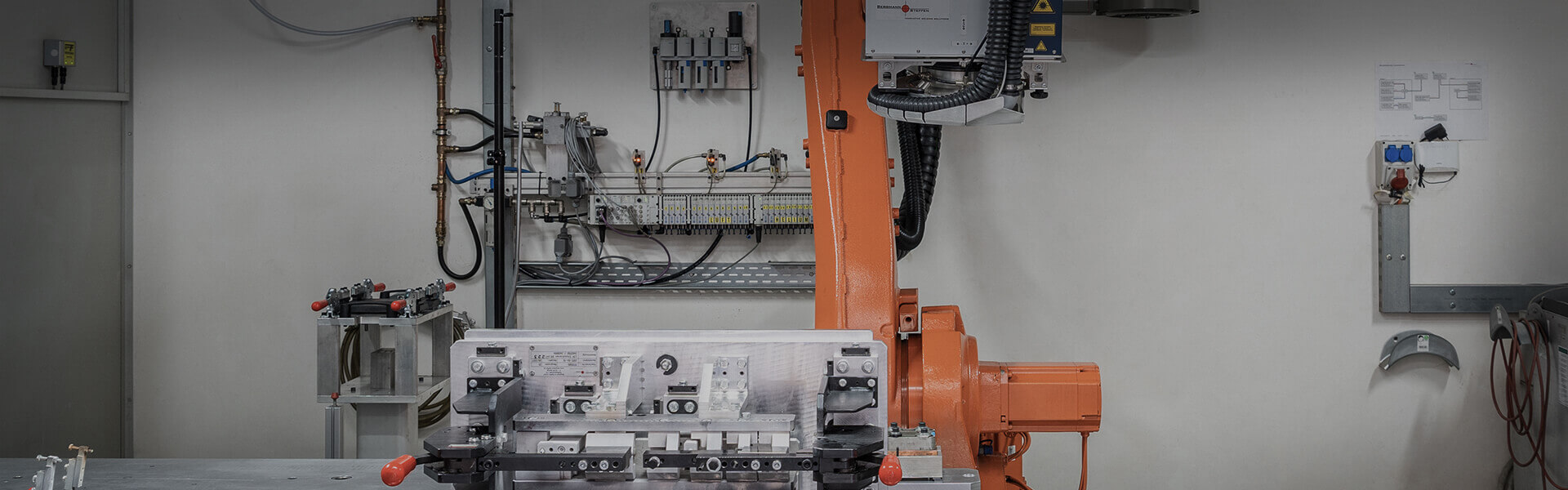

The Bergmann & Steffen Laser Centre:

Your advantage!

Our laser centre is available to you for tests, process development and optimisation, prototype and small batch production, as well as employee training.

Standard Equipment of our Laser Centre

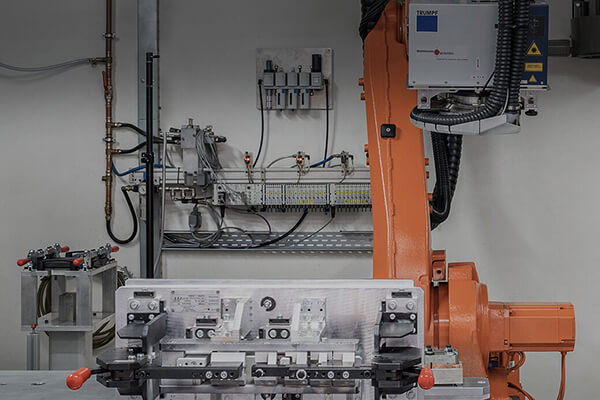

Trumpf I-PFO 3D

A remote laser welding system "Trumpf I-PFO 3D" with TruControl and TruTops I-PFO offline software for 3D programming.

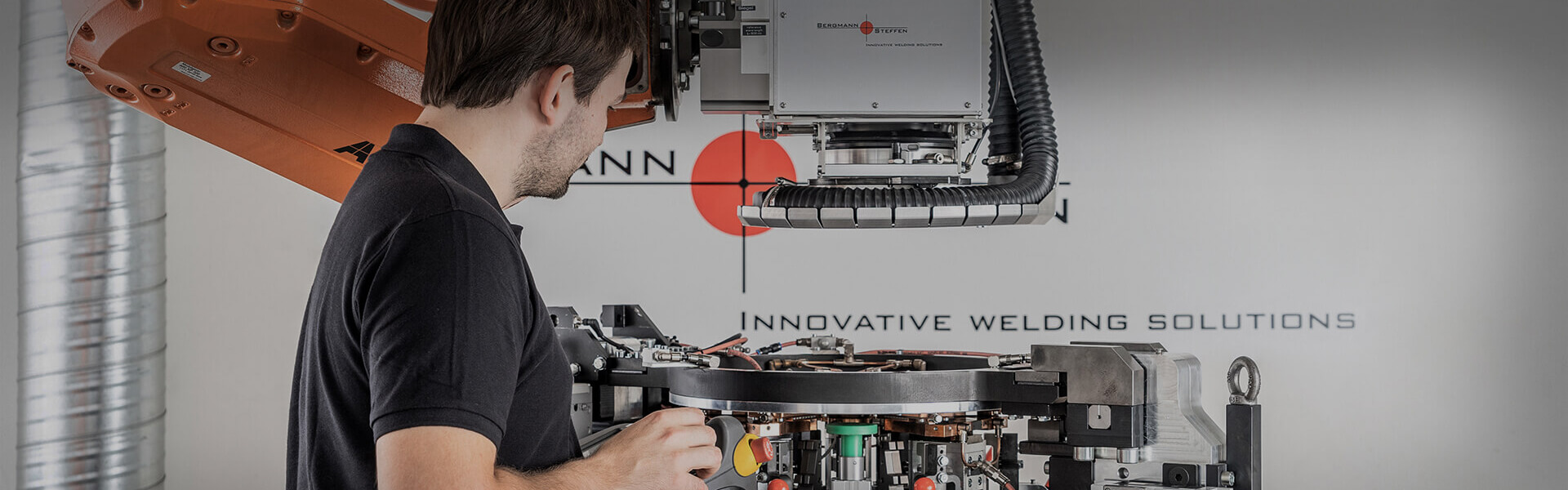

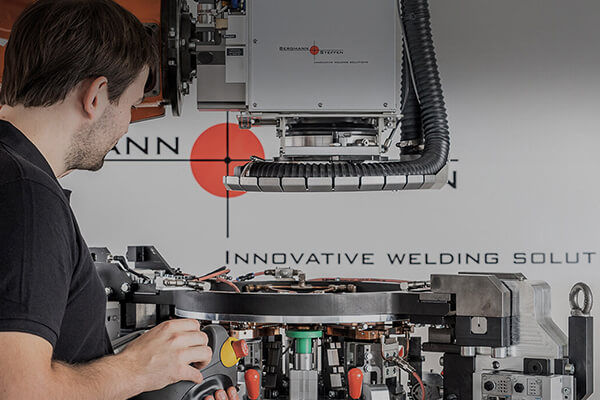

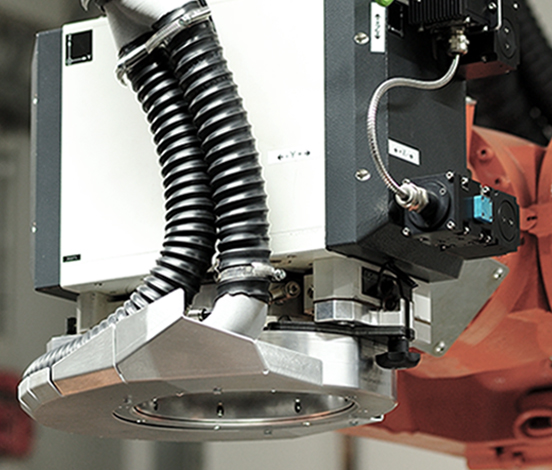

Scansonic ALO3

A tactile laser welding optics "Scansonic ALO3" with cold filler wire seam tracking for brazing and welding applications according to automotive standard.

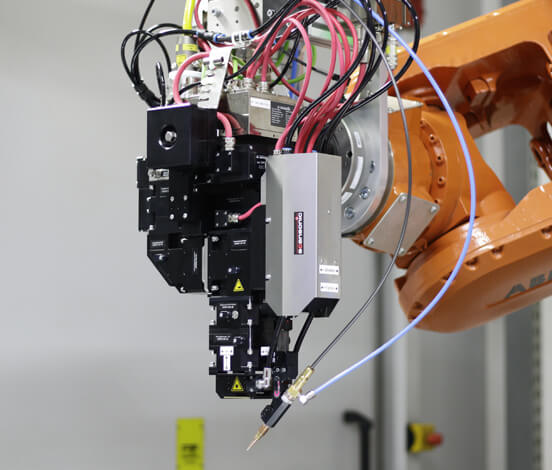

Scanlab Intelliweld FC-30V

A "Scanlab Intelliweld FC-30V" remote laser welding system with Blackbird "Robot Sync Unit" for offline-programming and Lessmüller's "Weldeye Remote" inline seam guiding system for process-reliable welding of fillet welds.

Trumpf BEO D70

The BEO D70 is a fixed optic from Trumpf, equipped with the Tornadoblade for fixed optics, which expands the laser centre from B&S. A special feature here is the adaptability of the focus diameter through the combination of different available laser light cables and focusing focal lengths. In this way, we can achieve focus diameters from 75 µm to 600 µm. In addition, a bifocal module can be installed, which creates two fixed focal points on the component surface.

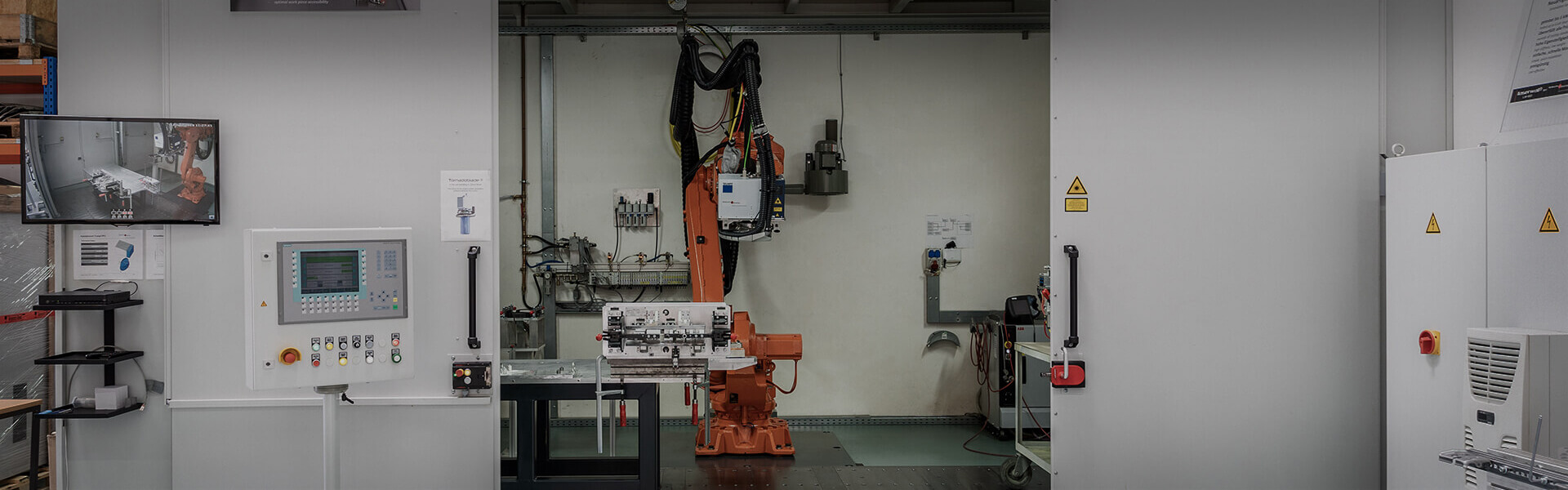

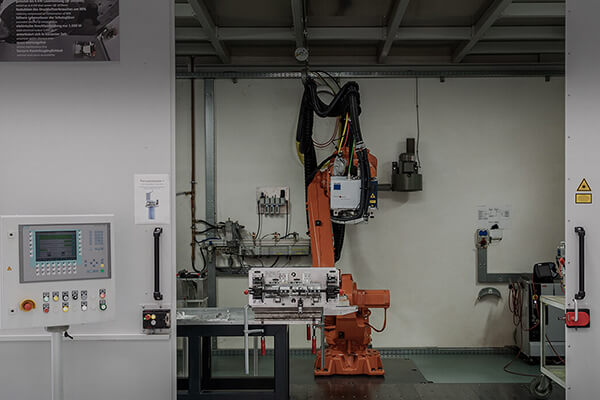

Equipment

- Two self-sufficient, active laser safety cabins with ABB industrial robot (s), positioner and own sequence control

- A fiber laser: Trumpf TruFiber 6000 S, 6 kW output with additional adaptation option for QD process fibres

- A "Scanlab Intelliweld FC-30V" remote laser welding system with Blackbird "Robot Sync Unit" and Lessmüller "Weldeye Remote" inline seam guiding system for process-reliable welding of fillet welds

- A remote laser welding system "Trumpf I-PFO 3D" with TruControl and TruTops I-PFO offline software for 3D programming

- A tactile laser welding optics "Scansonic ALO3" with cold filler wire seam tracking for brazing and welding applications.

- A Trumpf BEO D70 fixed optic with various focal lengths and bifocal module.

- Metallographic laboratory for process development, evaluation and documentation of welding results