Blower Airknife Technology

innovative blower airknife

for welding optics

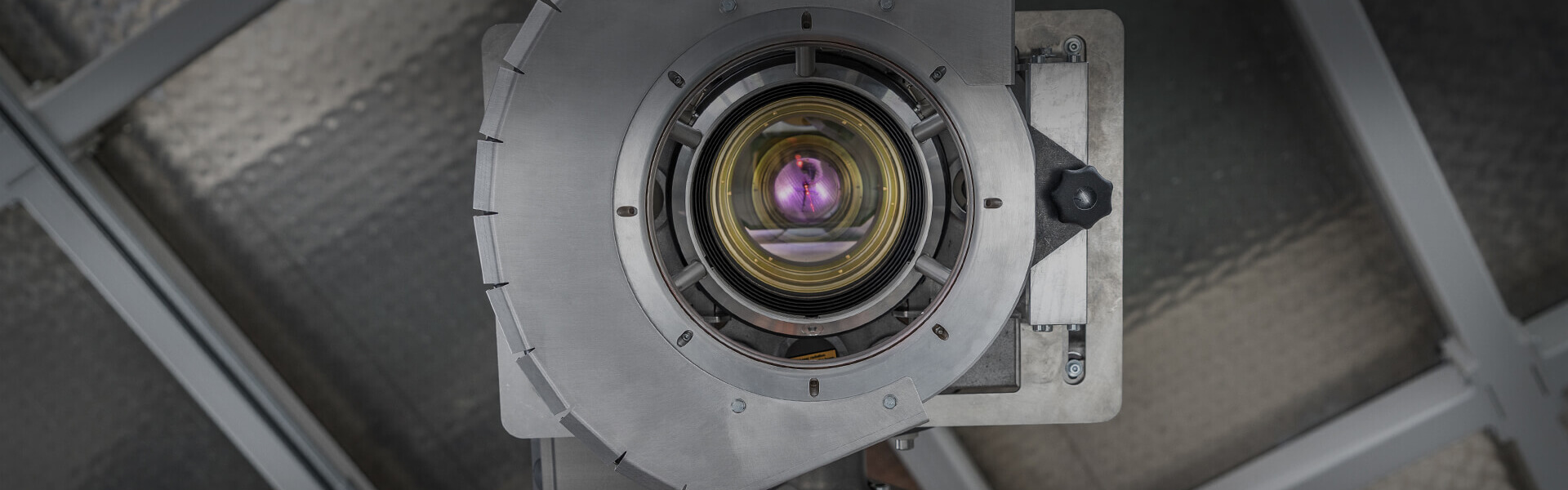

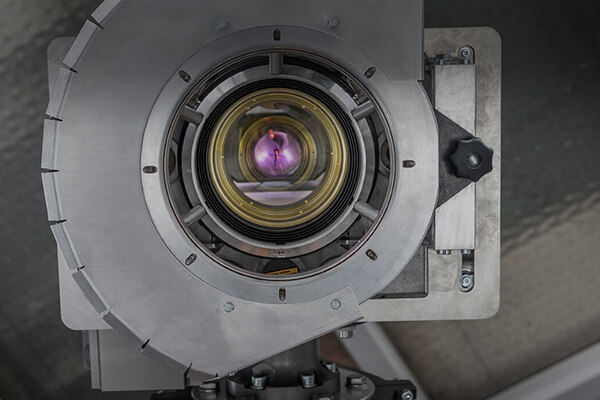

The Tornadoblade® deflects weld spatter from the point of origin, keeps the space between the optics and the process clean and thus increases the lifetime of the protective glass while drastically reducing the amount of compressed air required.

Since its market launch in 2017, compressed air crossjets have been successively replaced by blower-operated Tornadoblade® units, both for equipping new systems and retrofitting existing systems. Each one reduces the running operational costs for the owner, as the energy-intensive generation of compressed air is avoided.

Energy saved by all Tornadoblade® units up to now:

156420259 kWh

What does this mean for your company and your application?

The Tornadoblade® is available for both scan optics and fixed optics from all manufacturers.

For further information please contact us.

Jan Delskamp

Tel.: +49 (5225) 8786-30

j.delskamp(at)bergmann-steffen.de

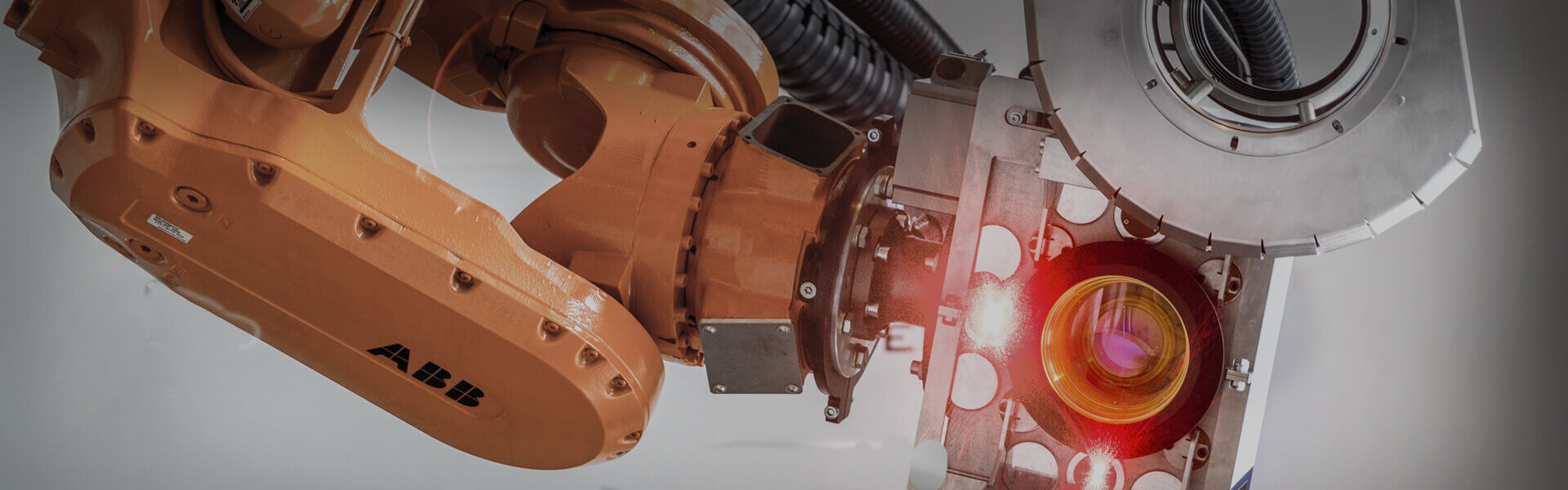

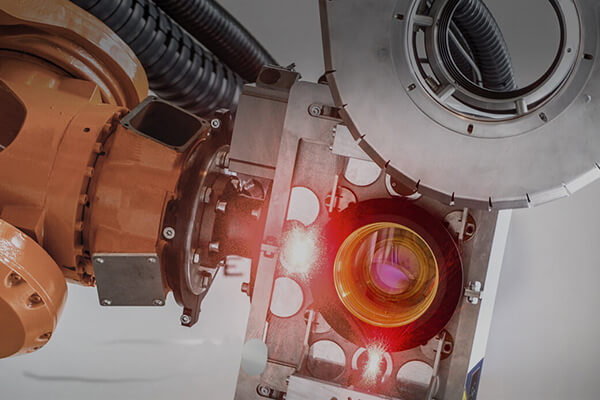

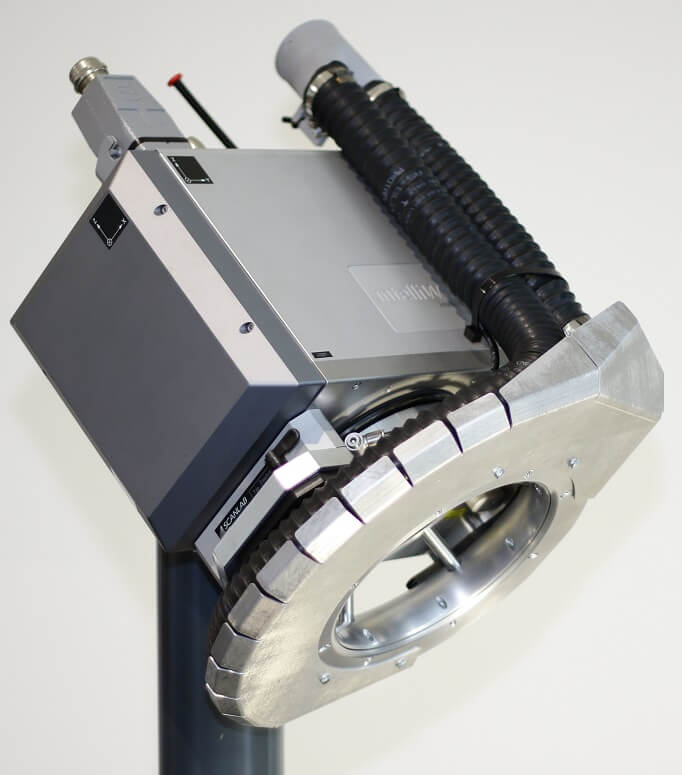

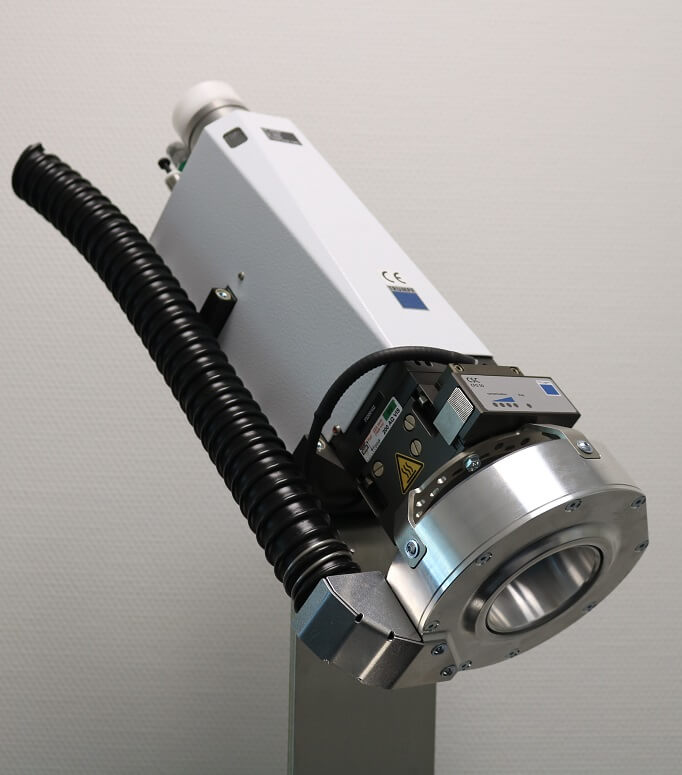

Tornadoblade®

compatible with welding scanners from Trumpf, Scanlab and Highyag

- Tested up to 8 kW laser power (@ 1070 nm)

- Reduces compressed air consumption by 98 %

- Supplementary blowing nozzles for process air on fixtures can be omitted

- Longer service life of the protective glass

Reduction in purchase costs for wear parts

Elimination of production interruptions for changeovers - Electrical connected load only approx. 4 kW

- Amortizes in a very short time, a/m maintenance-free

- Better access to workpiece

- Independent of direction

- Improves the weld seam quality

Deeper weld penetration with the same path energy - Stabilizes quality monitoring (e.g. LWM, 4D.watcher, SCeye, WELDEYE,...)

Further info about the product

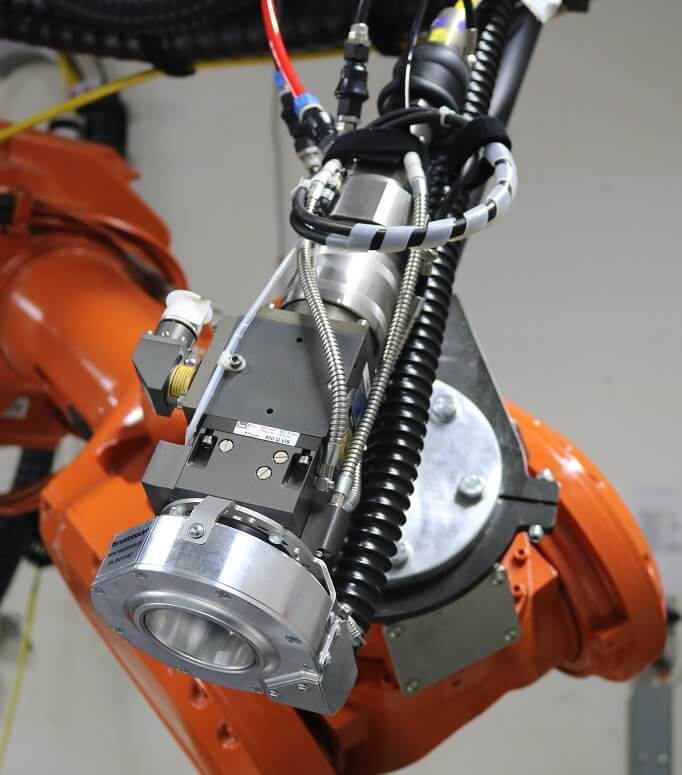

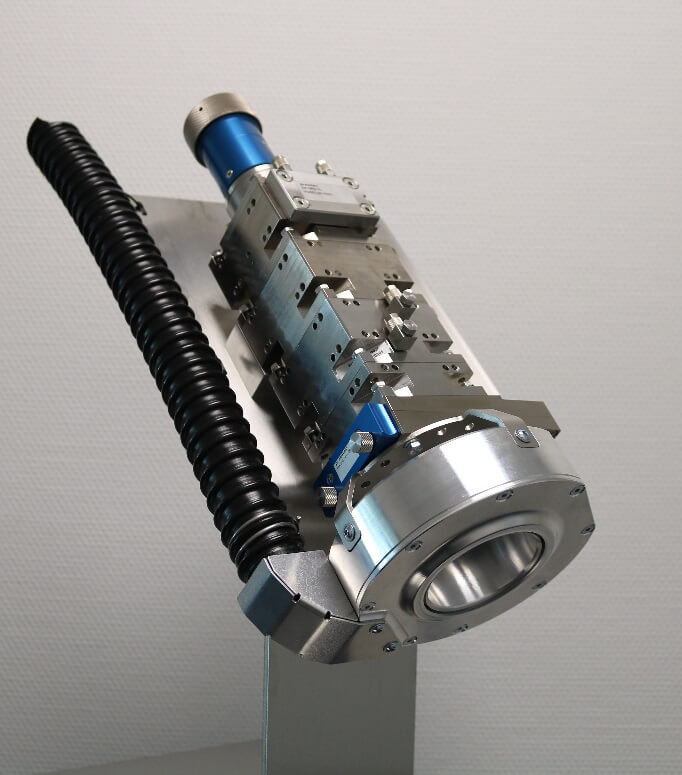

Tornadoblade®

compatible with fixed optics (from Precitec, Trumpf,...) and small-field scanning optics (from Scansonic,...), both robot- and axle-driven

- Tested up to 8 kW laser power (@ 1070 nm)

- Reduces compressed air consumption by 99 %

- Supplementary blowing nozzles for process air on fixtures can be omitted

- Longer service life of the protective glass

Reduction in purchase costs for wear parts

Elimination of production interruptions for changeovers - Electrical connected load only approx. 0.7 kW

- Amortizes in a very short time, a/m maintenance-free

- Better access to workpiece

- Independent of direction

- Improves the weld seam quality

Deeper weld penetration with the same path energy - Stabilizes quality monitoring (e.g. LWM, 4D.watcher, SCeye, WELDEYE,...)

Our Sales Partner Japan

INTECH Co., Ltd

Phone: +81-3-3301-9671

Email: sales(at)intech-jp.com

Web: http://www.intech-jp.com/bergmann&steffen.html

Our Sales Partner USA, Canada and Mexico