Research & Development

Bergmann & Steffen

own ideas and innovations

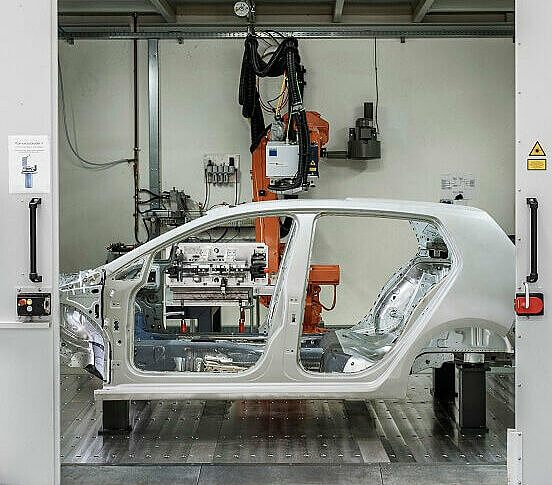

An increasingly important part of the laser centre's portfolio includes research and development. We do not want to be "just" the extended workbench, but to stand out on the market with our own ideas and innovations. This requires the development of own products or the constant optimisation of pre-existing products. The laser centre is used to test the concepts developed in the design department and manufactured in the production, and feeds the results and experience of the tests back to the departments. Thus a continuous development process in-house is possible and swiftly leads to new or improved products after a few development stages. We have already developed patented welding processes and fixture concepts, and have applied for a patent on two Bergmann & Steffen products. These are the llaserwall® - a passive laser protection wall for high laser power made from a new composite material - and the Tornadoblade® - a innovative and energy-efficient crossjet system without compressed air for laser optics.

One step ahead of development, research is an important catalyst for new ideas and innovations from Bergmann & Steffen. As a member of DVS for many years and participating in project-accompanying committees of various research projects, we gain a holistic overview of the research landscape and can thus work very purposefully on new or optimised solutions.