Remote Laser Welding

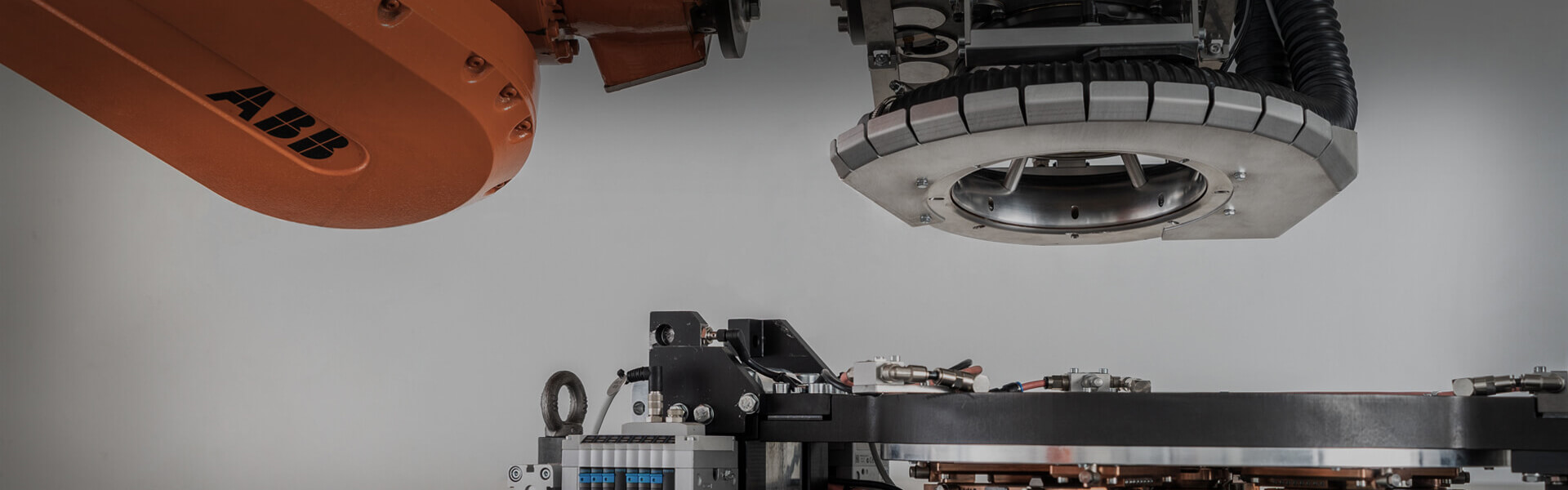

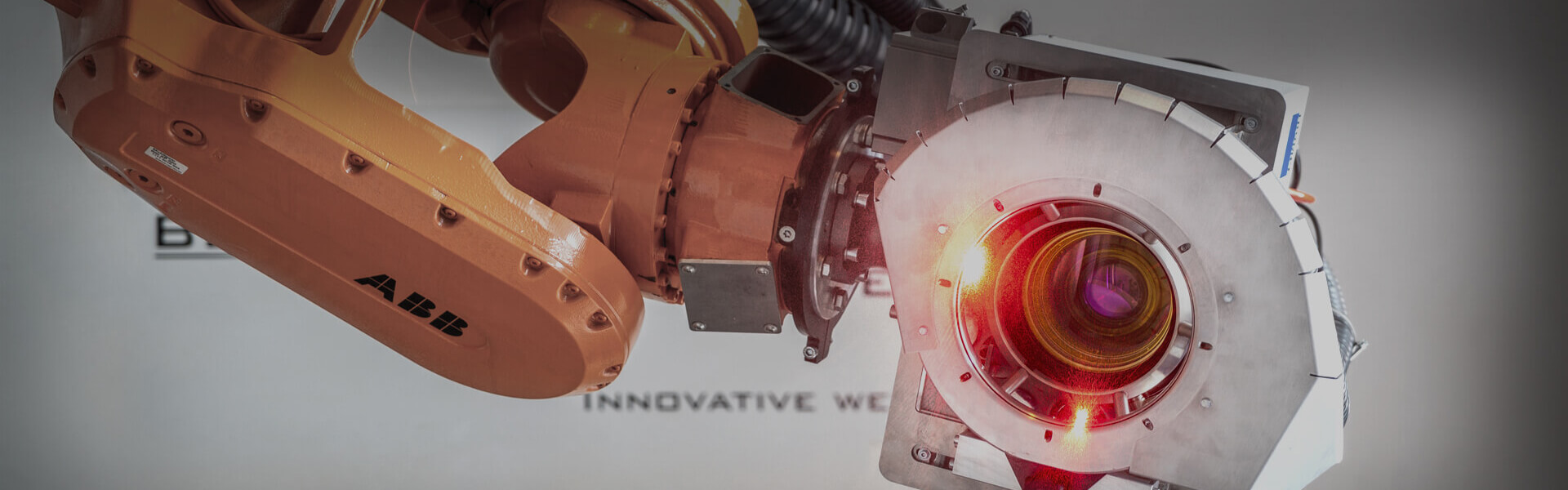

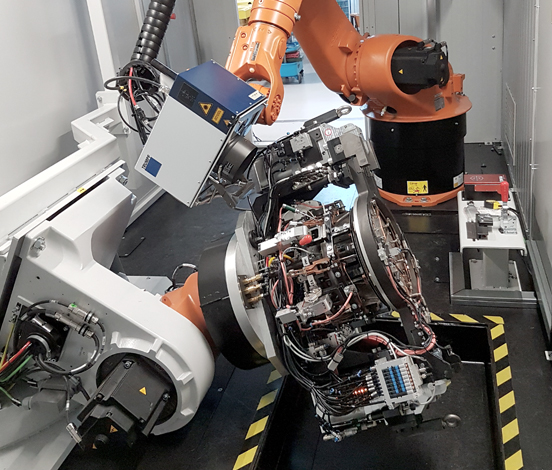

Standard industrial robot with

highly dynamic 3D laser-scanner

Remote or scanner welding is a special form of laser welding technology. Remote laser welding systems have large focal lengths, the laser beam is positioned over fast deflection mirrors, and the systems are often coupled to industrial robots. The robot moves the laser scanner in a continuous movement over the component, at the same time all welds in the working area of the laser scanner are welded in flight "on the fly".

The result is a remote laser welding system that uniquely combines the reach and agility of a robot with the impressive power of a laser scanner: an extremely precise and highly dynamic welding system for serial production.

This method is particularly suitable for 3-dimensional components, such as car front seats, car doors and other structural parts, which have a high number of shorter joints.

Fundamentals

With the Scanner Welding System, the laser beam of the solid-state laser is guided to the 3D laser scanner by means of a fibre optic cable and precisely directed to the component via the collimating, focusing unit and scanner mirrors that are integrated in the scanner. Highly dynamic galvometer drives guarantee a short positioning time. Non-productive times are reduced to a minimum. This method is particularly suitable for 3-dimensional components, such as car front seats, car doors and other structural parts, which have a high number of joint connections.

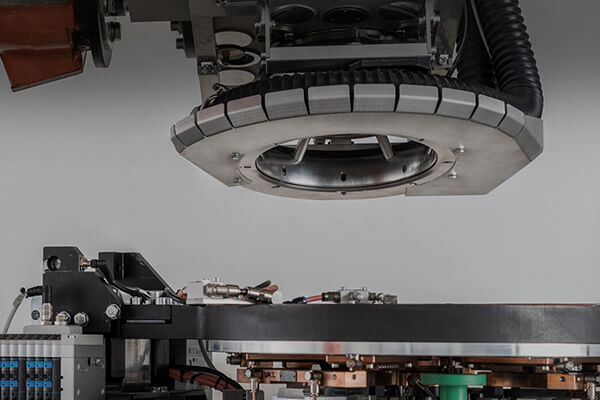

Fixture and system technology

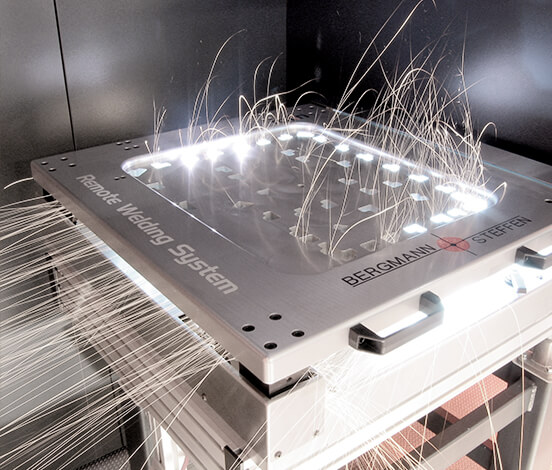

Remote Laser Welding - Fixture Technology

Our patented remote laser welding process and our patented clamping technology are consistently adapted to the remote laser welding process. For this purpose, the components are clamped by a large number of spring-loaded, pneumatic or hydraulic pressure units in a two-part welding tool. This makes it possible to securely fix components at almost any number of points in one clamping process.

The combination of aeration and venting technology, which is specially integrated into the tool, stabilises the process and makes it manageable even at high laser outputs. The extensive avoidance of shield gases and compressed air further increases the cost-effectiveness of our welding systems.

Remote Laser Welding - system technology

We deliver system technology specially adapted to the remote laser welding process.

Highly dynamic rotary indexing tables in combination with a sophisticated, fast lock system ensure minimal downtime and thus extremely high laser ON times.

We attach particular importance to the regulated aeration and venting technology within the laser welding cell - another important component for a successful laser process.