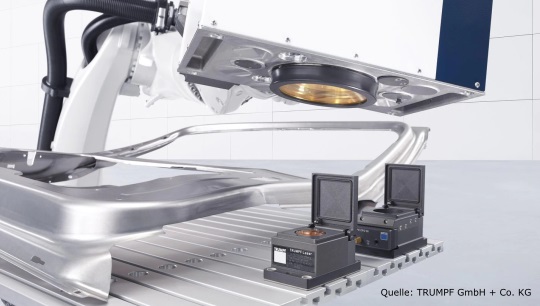

BrightLine Weld and OCT offer completely new possibilities.

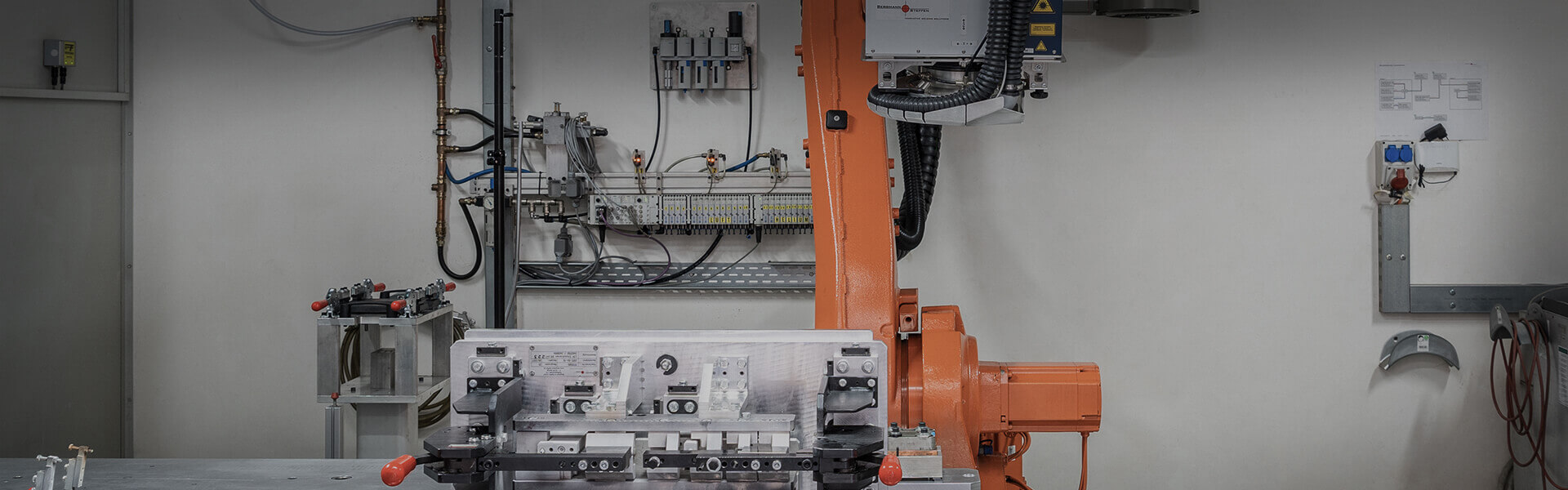

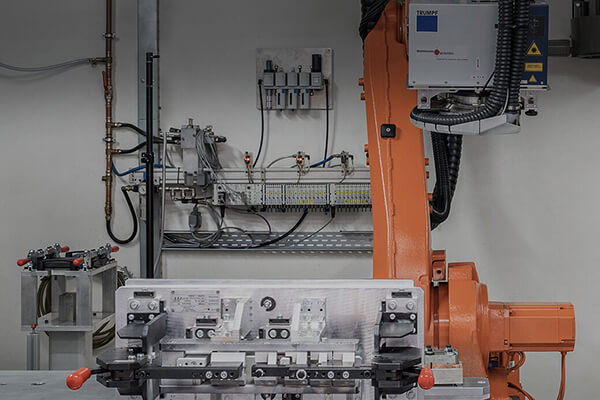

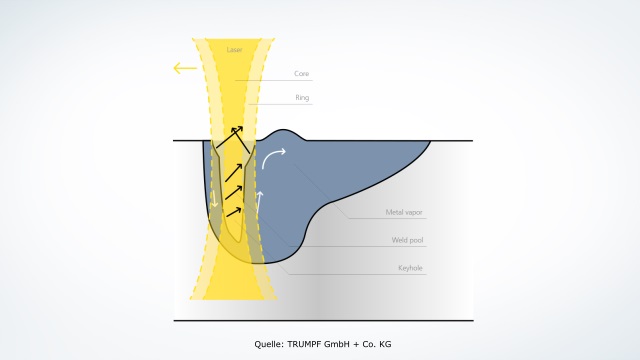

With the “BrightLine Weld” technology, the laser power is coupled into a special “2 in 1 laser light cable”. The laser power can be distributed among the core and ring. The division of the entire beam power into core and ring can be flexibly adapted to the respective welding application with the aid of a motor-driven wedge switch.

The aim of this development is to avoid spatter during laser welding, which can represent a significant quality deficit. Weld spatter occurs when the metal vapor escaping during deep welding accelerates the weld pool and spatter can escape from the back wall of the keyhole. Time-consuming post-processing steps for the components or cleaning work on the machine are often the result, which should be minimized by using "BrightLine Weld".

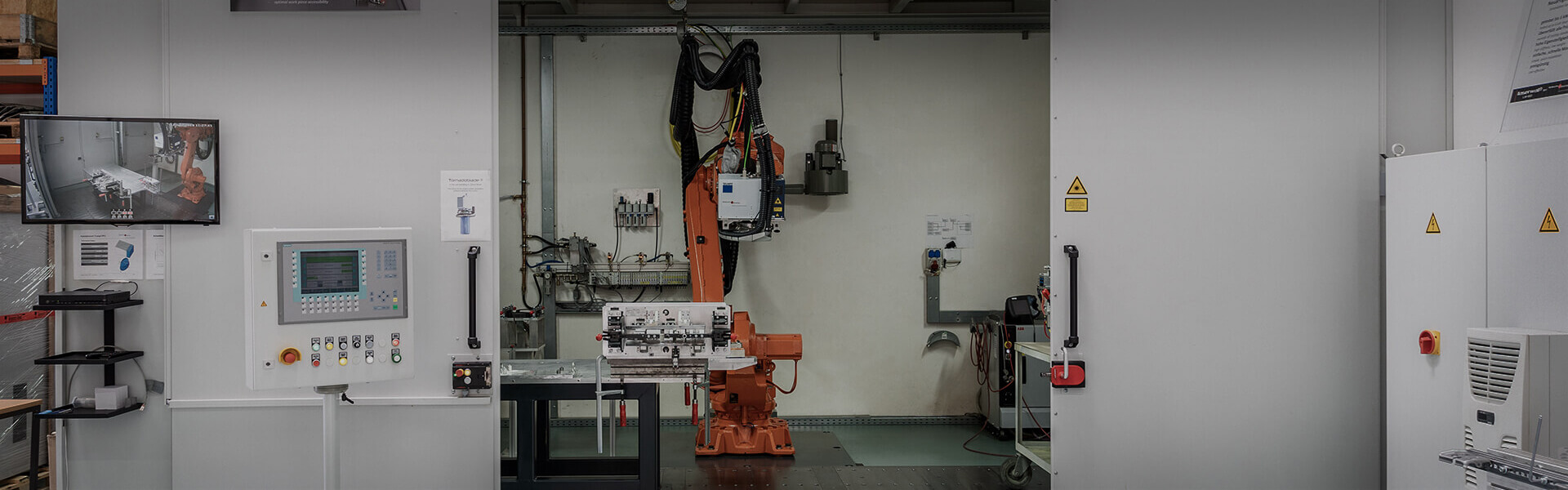

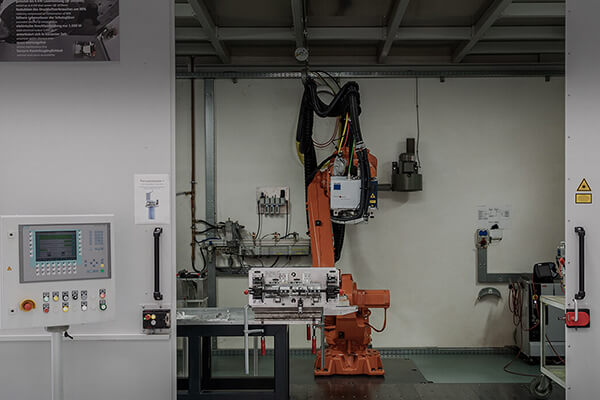

However, since many systems on the market are not operated with “BrightLine Weld” -capable lasers, we still have the option of operating the PFO 3D with a standard LLK (200 µm fiber diameter) in order to map prototype welds under the existing conditions. Further information on the Trumpf website.

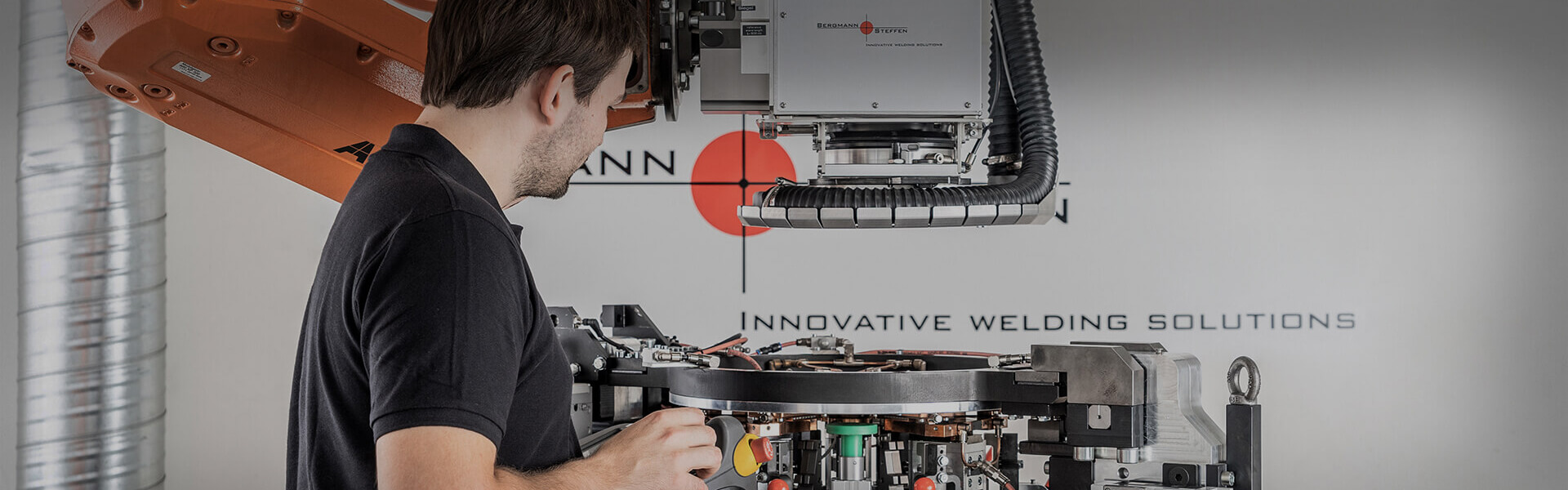

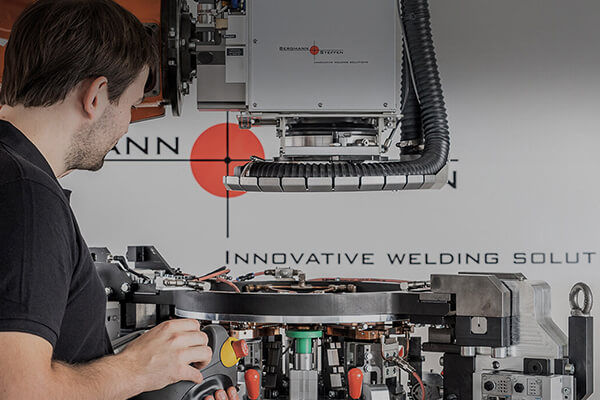

We have expanded one of our scanner optics (I-PFO 3D) with an OCT seam control (OCT = Optical Coherence Tomography) and monitoring. An OCT measuring beam regulates the seam position, can be used for the inline measurement of the welding depth or checks the quality of the welded seam. Some welding apllications can only be made pssible by using a seam position control (so-called end fillet welds on pressed sheet metal parts) or the reject rate can be minimized.

You can obtain further information about the various possible uses on the Trumpf website or directly from us. You can reach our Laser Application Center manager at +49 5225 8786 29 and by email.

In addition to the expansion with the OCT seam control, the "CalibrationLine" function was also retrofitted in the laser centre for demonstration purposes. This allows the focus position to be checked at regular intervals and corrected automatically. With an additional power measurement, an automated production process results in an absolutely controllable and repeatable welding result.

Quelle: Trumpf